- Home

-

About

-

Industries

- Capabilities

-

Solutions

Electronics SolutionsIoT SolutionsEnergy Storage SolutionsMotors

-

Technologies

The company offers a one-stop solution that covers the entire value chain process, designed to meet the diverse needs of our customers, enhance product value, reduce business risks, and increase competitiveness.

One-stop

solution

Aggressive action to enhance product value and competitiveness, reduce business risks and threats to intellectual property

Design and develop test and production equipment to improve operational efficiency

We developed IoT services related to smart home, healthcare, data management, and communication based on the advantages in the field of intelligent control

20+ years of experience, industry leading development team

Strict and standardized supply chain management system

Three global manufacturing centers to ensure quality and quantity delivery

Standardized quality management system, rich experience in quality control

Help customers continuously optimize costs

Our company is currently one of the leading Chinese companies in the global home appliance sector, boasting the highest number of core patents, the most robust R&D team, and the most professional technical solutions.

R&D investment accounts for more than 12% of sales revenue for three consecutive years.

We have 1100+ R&D engineers who specializes in intelligent controller and Internet of Things and core R&D team with 15+ years experience.

2000

+Accumulatively applied for over 2000 core patents

800

+Cumulative application for invention patents 800+ items

600

+600+intelligent controller engineers+

500

+500+ IoT engineers

H&T Lab has been certified as China National Class, and UL Witness Level.

Safety Test

EMC/EMI

Reliability Test

LED Lighting

Chemical analysis

RoHS / IC Test

Components / Failure Analysis

Failure Analysis

System Failure Analysis

Assembly Process Failure Mechanism Interpretation

Component and Device Failure Mechanism Interpretation

Material Failure Mechanism Interpretation

Mexico(Monterrey)

steven.zhang@szhittech.com

Italy

cindy.long@szhittech.com

Romania

rock.cao@szhittech.com

Qingdao

Dennis@szhittech.com

Hefei

yongyou.li@szhittech.com

Hangzhou

James.li@szhittech.com

Shenzhen

huozq@szhittech.com

Vietnam(Binh Duong)

pingyang@szhittech. com

Vietnam(Hai Phong)

steven.zhang@szhittech.com

9

Manufacturing Centers

8

million pcsAnnual Production Capacity

550,000

㎡Total Area

300

+Production Lines

9

Manufacturing Centers

8

million pcsAnnual Production Capacity

550,000

㎡Total Area

300

+Production Lines

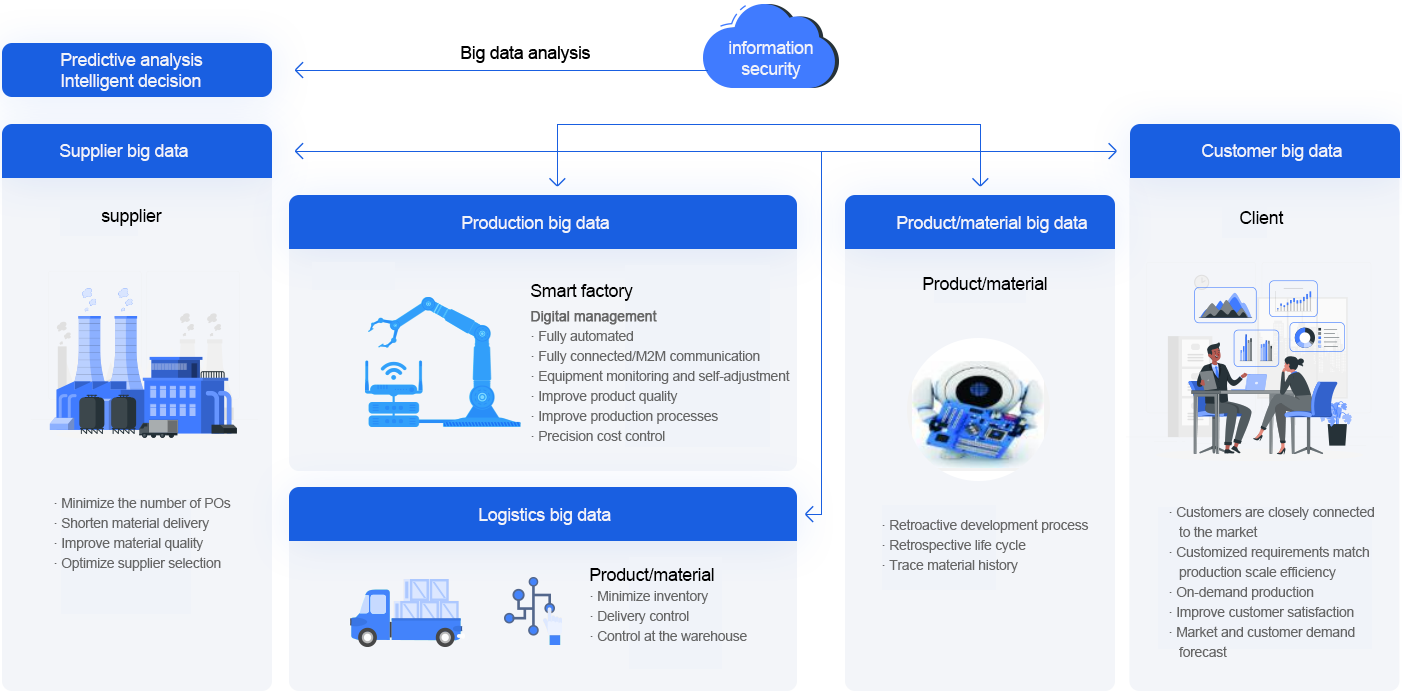

IOT equipment connection

Operational mobilization

Digitalization of information

Intelligent decision making

Production Line Execution

CTQ (Critical To Quality) Audit

Customer Audit/Complaint Management

Customer On-site Feedback Improvement

FAE (Field Application Engineering) Activities

Process Audit (4M)

Abnormal Risk Assessment

SFC (Shop Floor Control) System Execution

ECN (Engineering Change Notice)/PCN (Product Change Notification)

DFX (Design for X, where X could be manufacturing, assembly, cost, etc.)

Critical Component List

Feasibility Assessment

ICT (In-Circuit Test) + FCT (Functional Circuit Test)

BOM (Bill of Materials) Cost Estimation

MP (Mass Production) + W8 (Wait Time)

HASA (Hazard and Operability Study) / Environmental Testing / Life Testing...

On-site Data Collection/Analysis

NPI (New Product Introduction) Audit

Laboratory Certification

Component Quality Certification

ISO 9001/14001/45001

IATF 16949 + VDA 6.3

ISO 13485

ESD (Electrostatic Discharge)

Internal and External Audits

KPI (Key Performance Indicator) Summary

QIT (Quality Improvement Team)

QCC (Quality Control Circle)

Six Sigma

Lean Manufacturing